About Us

All*Star continues to be a family-run business. We provide quality gasketing products and techniques to the CNC industry for over 20 years and counting. We listen to our customers' successes and failures when it comes to vacuum holding. Those conversations over time have led to the creation of the CNC Gasketing Product Line that exists today.

The reason our customers keep coming back to us for our products and assistance is that we have proven to maximize the effectiveness of the vacuum-holding ability of the CNC Routers they own and operate. The only way to improve a vacuum's performance is with gasketing material. Gasketing is the only tool available that can change a simple, down-draft application to a powerful vacuum clamp one. These are two different sciences and the vacuum clamping technique proves to be vastly superior to that of simple downdraft.

All gaskets are not created equal. The Gasketing that we engineer and produce is held to the highest standard in quality, workmanship, and accuracy insuring that the material has maximum lifetime and recovery, resulting in improved yields and quality workmanship on CNC routers.

Watch a Quick Video About Us

Grid Gasketing

Grid Gasketing is the non-adhesive material used in the perimeter of the CNC Router table/pod itself. Depending on the type of router that is being used, both square and rounded products are available. The goal is to fill the channel width-wise and stand proud above the table roughly 1/16 of an inch. This will create an air-tight seal under your spoil board/fixture board.

In Board Gasketing

In-Board Gasketing products are for creating dedicated fixtures for dedicated long-term parts. The benefits gained from utilizing a proper dedicated fixture are enormous. Placed in the pre-routed channels of a non-porous fixture board, these tools maximize vacuum performance, with accurate z-depth tolerances, extended tooling life, and more. If you are doing repetitive parts, do it with In-Board Gasketing.

Vacuum Clamping Gasket Kits

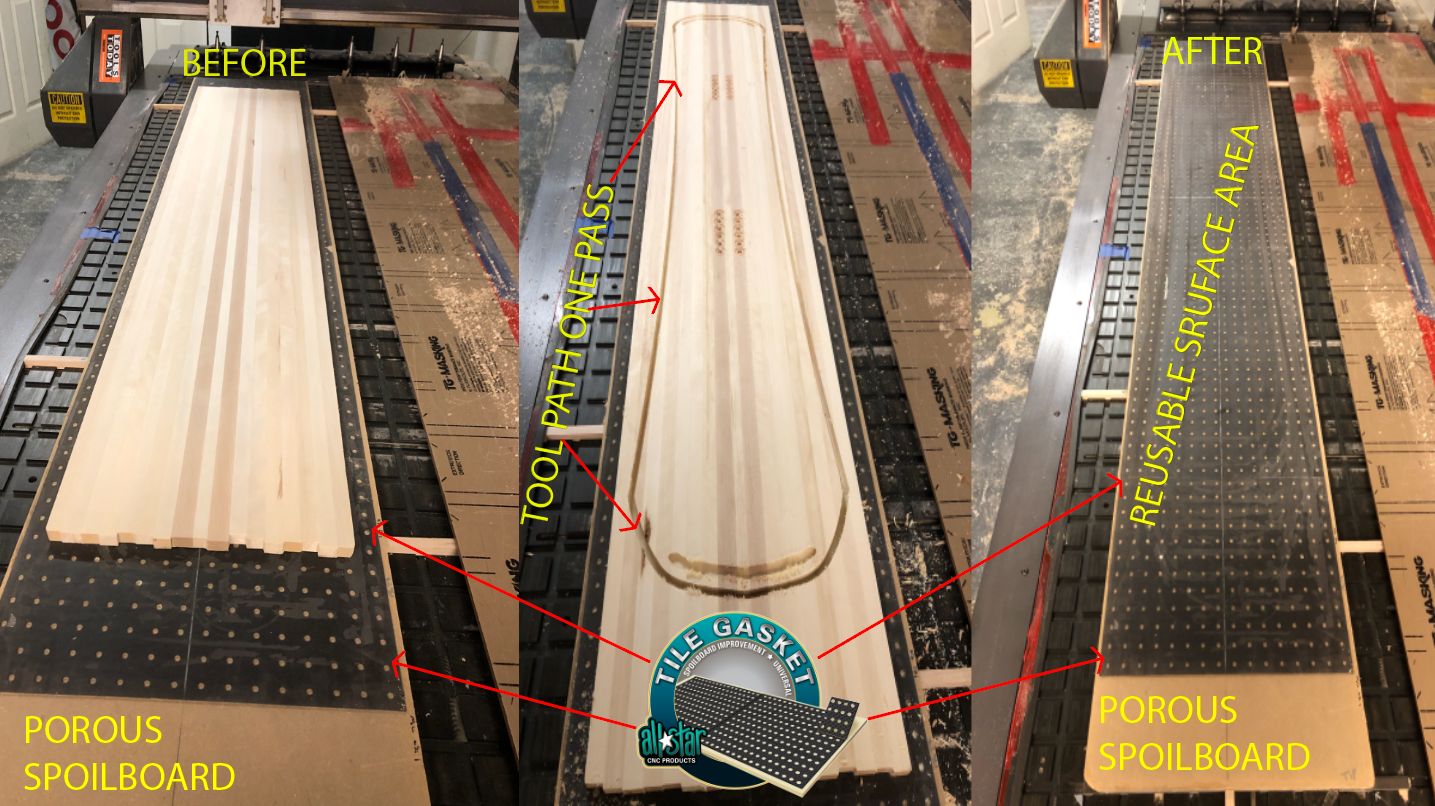

Our All Star Vacuum Clamping gasket kits come with everything you'll need to have your vacuum table holding parts stronger than ever. Each kit includes two bags of Grid Gasket precision cut specific to your table's channel dimensions ensuring an air-tight fit when sealing to your spoilboard. Also included is our patented Tile Gasket - a real game changer for holding parts on top of your works surface. Utilizing the physics behind vacuum clamping, Tile Gasket is far more powerful and efficient in holding firm even the smallest parts when compared to down-drafting on an open MDF spoilboard. Click here to see how the principle of Vacuum Clamping work. When you receive your kit, not only will you get gasket for clamping, but also application notes, handy magnetic conversion charts, and other fun swag and support.